There are many types of desiccant. According to the characteristics, it can be divided into physical adsorption desiccant and chemical desiccant. According to the raw materials, it can be divided into silica gel desiccant, calcium chloride desiccant, montmorillonite desiccant, live ore desiccant, molecular sieve. Desiccant, etc.

Different types of desiccant ingredients are also different:

Silica gel desiccant is a physical adsorption desiccant that does not change its shape before and after moisture absorption. The main component is silica (SiO2), which is usually prepared by reacting sodium silicate and sulfuric acid, and undergoing a series of post-treatment processes such as aging and acid foaming. Silica gel desiccant is insoluble in water and any solvent, non-toxic and tasteless, chemically stable, and does not react with any substance except strong alkali and hydrofluoric acid. Generally, in the case of a temperature of 30 ° C and a relative humidity of 90%, the moisture absorption rate of the silica gel desiccant is between 25% and 30%. The silica raw materials used by Chunwang will be slightly better than this data. The most suitable moisture absorption environment for silica gel desiccant is room temperature (20~32 °C) and high temperature (60~90 °C), which can reduce the relative humidity of the environment to about 40%.

Calcium chloride desiccant is a chemical desiccant. It is a white powder before moisture absorption and a solid gel after moisture absorption. The main component is calcium chloride (CaCl2), which is prepared by mixing hydrochloric acid and carbonic acid, and is prepared by reaction synthesis, filtration, evaporation, concentration, drying, etc.; the taste is slightly bitter, odorless, and the aqueous solution is colorless. Calcium chloride desiccant is environmentally friendly and degradable. It is non-toxic and harmless to the human body. It has good compatibility with the target product and has no pollution to the environment. Generally, at a temperature of 37 ° C and a relative humidity of 90%, the calcium chloride desiccant can have a moisture absorption rate of 200% to 280%, which is nearly 10 times that of a common desiccant. Due to the excellent moisture absorption effect of calcium chloride desiccant, it is being accepted and used by more and more customers.

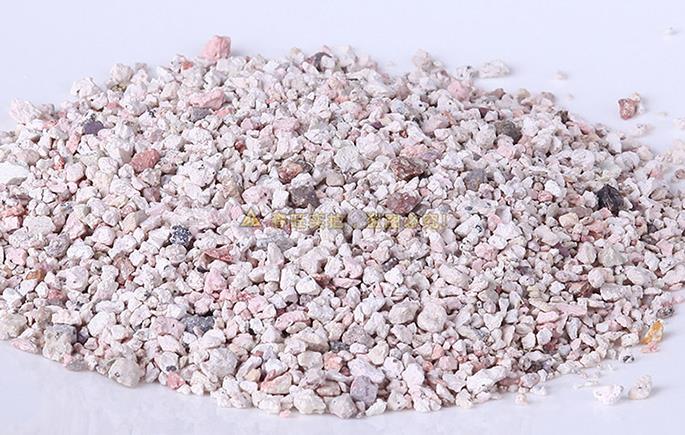

The montmorillonite desiccant is a physical adsorption desiccant that does not change its shape before and after moisture absorption. The montmorillonite desiccant is produced by natural montmorillonite ore after high temperature heating of organic matter carbonization, montmorillonite ore body expansion, steam treatment, drying, drying, activation, crushing and sieving, and montmorillonite is a A mineral silicate with a chemical formula of Al2O3·4SiO2·nH2O. It is a natural, non-toxic, degradable, healthy and environmentally friendly desiccant with a neutral pH and no corrosive substances. It has good moisture absorption performance in low humidity environment, so it is often used in metal and high-precision electronic and electrical products, such as electronics, electrical appliances, instrumentation, hardware equipment, etc. Generally, in the case of a temperature of 30 ° C and a relative humidity of 90%, the moisture absorption rate of the silica gel desiccant is between 18% and 25%.

The live ore desiccant is a high-activity physical adsorbent desiccant made of natural safe and non-toxic attapulgite. The appearance is grayish white, grayish gray, and maintains a stable moisture absorption function under various humidity conditions. The live ore desiccant has a moisture absorption rate slightly greater than 20% at a temperature of 25 ° C and a relative humidity of 80%. It can be completely degraded without any pollution to the environment.

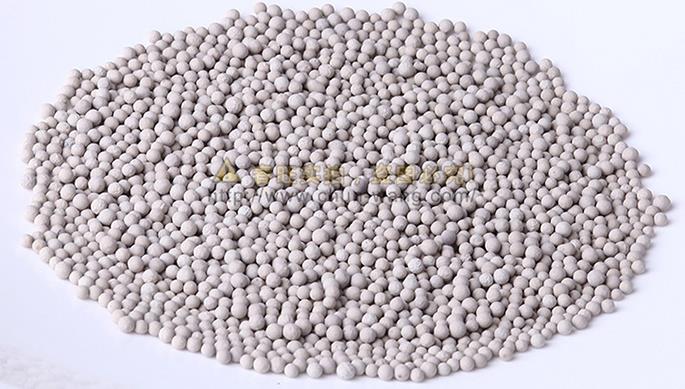

Molecular sieve desiccant is a kind of crystalline aluminosilicate (molecular formula: Na2O.Al2O3.2.0SiO2.4.5H2O), which is a desiccant product which is artificially synthesized and has strong adsorption to water molecules. Mainly composed of silicon-aluminum through the oxygen bridge to form an open skeleton structure, in the structure there are many pores with uniform pore size and well-arranged holes with large internal surface area. The pore size of the molecular sieve can be controlled by the difference in processing technology. In addition to adsorbing water vapor, it can also adsorb other gases. At high temperatures above 230 ° C, water molecules are well accommodated. The molecular sieve desiccant has a moisture absorption rate of slightly more than 23% at a temperature of 25 ° C and a relative humidity of 80%.

All trademarks shown here are for reference purposes only. They are the property of their respective owners, and we are not authorized to sell items bearing such trademarks.