18years Famous Desiccant Brand

We are a professional oxygen absorbers manufacturer with 18 years of professional industry knowledge and a modern industrial plant of 15,000 square meters.

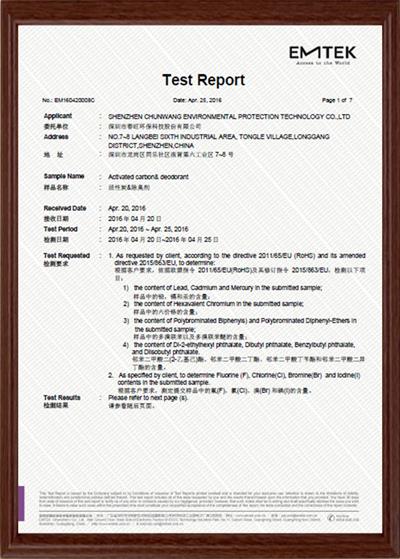

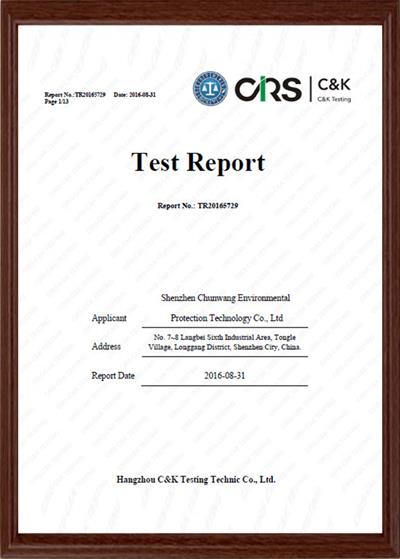

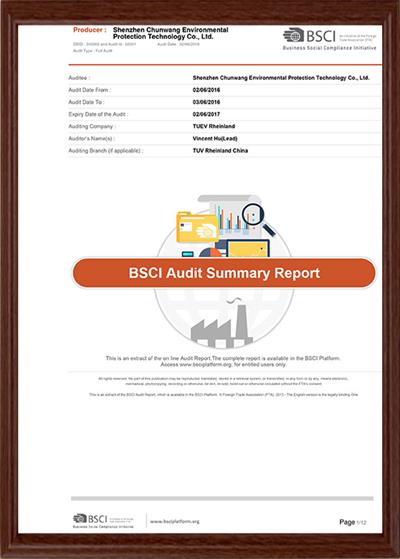

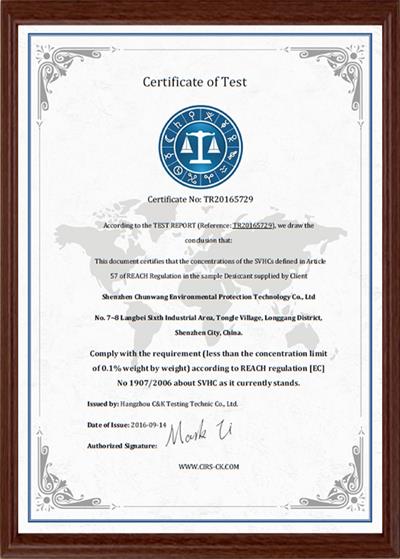

Qualification Certificate

We had passed the ISO9001:2015, ISO14001:2015, BSCI, GMP and Walmart audits. Our products comply with RoHS certification and other certificates.

Safe Materials

The desiccant raw materials have been optimized, do not contain DMF, and comply with RoHS and Reach standards.

Excellent Services

Our sufficient production capacity ensures delivery dates, and complete supervision system ensures product quality. Work with a professional shipping team to ensure safe delivery.

Oxygen Absorbent use in fried nuts to remove oxygen, keep food fresh and extend their shelf life.

Food use iron powder oxygen absorbent packet, to prevent oxidation of food

Oxygen absorbent for food package Introduction: Oxygen absorbent is an additive that can absorb oxygen and slow down the oxidation of food. It can effectively inhibit the growth of molds and aerobic bacteria, prolong the shelf life of food, and play a good role in preventing...

The oxygen absorber is also named De Sanso agent. It can effectively inhibit the growth of aerobic bacteria and mold by absorbing the oxygen in the packaging, preventing from mildew, lipid oxidation, insects, aging, discoloration, rust, and extend shelf life.

Food Safe Oxygen absorber is also named De Sanso agent. It can effectively inhibit the growth of aerobic bacteria and mold by absorbing the oxygen in the packaging, preventing from mildew, lipid oxidation, insects, aging, discoloration, rust, and extend shelf life.

50cc Oxy Sorb Oxygen Absorbers is also named De Sanso agent. It can effectively inhibit the growth of aerobic bacteria and mold by absorbing the oxygen in the packaging, preventing from mildew, lipid oxidation, insects, aging, discoloration, rust, and extend shelf life.

The oxygen absorber is also named De Sanso agent. It can effectively inhibit the growth of aerobic bacteria and mold by absorbing the oxygen in the packaging, preventing from mildew, lipid oxidation, insects, aging, discoloration, rust, and extend shelf life.

Oxygen absorber is also named De Sanso agent. It can effectively inhibit the growth of aerobic bacteria and mold by absorbing the oxygen in the packaging, preventing from mildew, lipid oxidation, insects, aging, discoloration, rust, and extend shelf life.

Oxygen absorbers are small packets that contain iron powder and salt. They work by removing oxygen from a sealed container, which helps prevent spoilage, discoloration, and the growth of bacteria and fungi. Oxygen absorbers are commonly used in the food industry to extend the shelf life of products such as jerky, dried fruits, and nuts. They can also be used in the pharmaceutical and electronics industries to protect products from moisture and oxygen damage.

How do Oxygen Absorbers Work?

A simple reaction takes place between iron and oxygen. When oxygen reacts with ferrous iron, it oxidizes and starts to rust. To ensure that maximum oxygen molecules react with ferrous iron oxide, sodium is added to the sachet. This promotes the reaction in an environment with low humidity. Multiple single iron and oxygen molecules keep reacting to form iron oxide. This continuously keeps reducing oxygen in the sealed container.

●Helps retain fresh-roasted flavor of coffee and nuts

●Prevents oxidation of spice oleoresins present in spices themselves and in seasoned foods

●Prevents oxidation of vitamins A, C and E

●Extends life of pharmaceuticals

●Inhibits mold in natural cheeses and other fermented dairy products

●Delays non-enzymatic browning of fruits and some vegetables

●Inhibits oxidation and condensation of red pigment of most berries and sauces

●Oxygen deprivation contributes to a pest-free environment in museums

In Conjunction with Vacuum Sealer Bags

When vacuum sealing foods, use oxygen absorbers to remove oxygen from the sealed vacuum bags. Oxygen absorbers help to prevent molding and the growth of aerobes, does not mix with food, and significantly extends the shelf life of your items.

In Conjunction with Storage Containers

Oxygen absorbers can also be used with deli containers or storage containers and canisters. They will keep fresh the items that you may not want to crush by vacuum sealing. If you open your container, remove your items, and then close the container, the oxygen absorber will still retain its functionality.

To Preserve Non-food Items

Historical documents, art, and other precious artifacts can be harmed by the presence of oxygen- leading to rapid deterioration, mildew, mold, and other contaminants. When properly used, oxygen absorbers can reduce the oxygen level in the surrounding environment to approximately 0.01%.

Oxygen absorbers can be used to preserve foods that contain 10% moisture or less. Storing the foods in an oxygen reduced environment can lead to botulism poisoning if the moisture and oil content exceeds the permissible limit.

Foods That Can be Stored with Oxygen Absorbers

●Natural cheese and other dairy products

●Prevents fruits and vegetables from browning due to non-enzymatic process

●Inhibits oxidation and buildup of red color in most berries and sauces

●Bread, cookies, cakes, pastries

●Nuts and snacks

●Candies and confectioneries

● Whole fat dry foods

●Dried fruits and vegetable

●Spices and seasonings

●Flour and grain items

●Fresh and precooked pasta and noodles

●Vitamins

Foods that NOT be Stored with an Oxygen Absorber

●Brown Rice

●Jerky

●Granola

●Pearled Barley

●Dried eggs

●Milled grains (other than rolled oats)

●Brown sugar

●Nuts

●Leavening agents (baking soda/baking powder)

●Salt/Sugar

●Place all of the jars or vacuum sealing bags on your table.

●Wearing gloves, fill all of them with the food to be preserved (using a funnel prevents spills and loss). Gloves, prevent your oils or moisture to contaminate the food.

●Put the jar lids next to the jars, or have the vacuum sealer ready to go and warmed up.

●One person opens the bag of absorbers and drops one quickly into each container.

●The other person runs behind, sealing lids or vacuum-sealing (a bit slower).

●Once you are done using them from the package, be sure to re-seal that package so that the leftovers will be there when you need them 6 months from now.

Which is Better, Desiccant or Oxygen Absorber?

The decision to use either oxygen absorbers or desiccants ultimately depends on the type of product you are storing or transporting. Here are some factors to consider:

If your product is sensitive to oxidation, such as nuts, seeds, or dried fruits, oxygen absorbers are the best choice. They will help to remove oxygen from the packaging, preventing oxidation and prolonging the shelf life of the product.

On the other hand, if your product is sensitive to moisture, such as pharmaceuticals, electronics, or leather goods, desiccants are the best choice. They will help to absorb moisture from the packaging, preventing damage to the product.

The type of packaging you use can also affect the choice between oxygen absorbers and desiccants. Oxygen absorbers work best in airtight packaging, such as vacuum-sealed bags, whereas desiccants are effective in any type of packaging, as long as they are in direct contact with the product.

The storage conditions of your product can also affect the choice between oxygen absorbers and desiccants. Oxygen absorbers work best in low-humidity environments, whereas desiccants work best in high-humidity environments.

We had passed the ISO9001:2015, ISO14001:2015, BSCI, GMP and Walmart audits. Our products comply with RoHS certification and other certificates.

All trademarks shown here are for reference purposes only. They are the property of their respective owners, and we are not authorized to sell items bearing such trademarks.