Due to the nature of the container and the climatic differences around the world, the demand for desiccant has always existed. In essence, temperature changes can cause condensation. Temperature changes of around 20 degrees in the container are not uncommon. When the container is exposed to the tropical sunlight during the day, the temperature will drop at night and moisture will be generated, resulting in moisture damage to the cargo. This process is repeated day after day, and the damage to the goods can be quite serious. The water in the cargo is “extracted” one at a time and then condensed again onto the surface of the cargo. Most of the goods contain water-containing items. If it is not the goods themselves, they may be wooden boxes or corrugated boxes that package goods, or even the floor of the container. Even if any items in the container are absolutely free of moisture, consider preventing moisture damage. In the longer time, even if there is no condensation, the higher relative humidity will cause the cargo to wet.

The sales volume of China's desiccant manufacturer “Shenzhen Chunwang Environmental Protection Technology Co., Ltd.” is growing. Its products have covered all provinces, municipalities, autonomous regions, Hong Kong, Macao and Taiwan, Europe, North America, South America, Southeast Asia, etc. Country and region. Desiccants are used especially in the transportation of machine parts and glass. The company's latest product is "Container Desiccant [Cactus Guardian]", which is formulated with calcium chloride, a converted starch product and other ingredients. The desiccant in the bag absorbs moisture and becomes a jam-like substance, and does not leak even in the place where the humidity is the highest. The company recommends that six items are placed in a 20-foot box and 12 in a 40-foot box, with detailed instructions for specific types of goods. The research and development staff of “Shenzhen Chunwang Environmental Protection Technology Co., Ltd.” is developing new products with better performance.

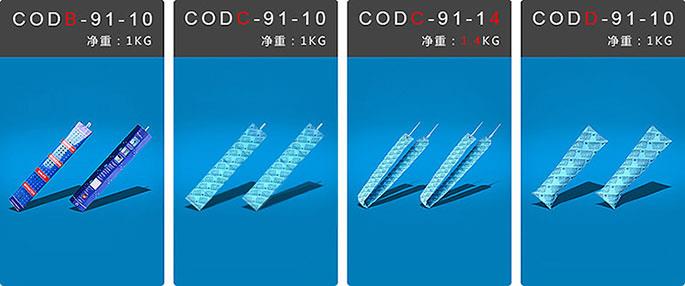

Absormatic, a Swedish desiccant manufacturer, believes that effective moisture-proof products must meet two objectives. First, condensation must be avoided or at least minimized when the temperature changes rapidly. Secondly, higher relative humidity must be avoided over a longer period of time. Since its inception in 1995, Absormatic has introduced three generations of desiccant products. The latest generation, called Absormatic III, contains 1 kg of calcium chloride, surrounded by a porous material that allows air and moisture to pass through but blocks the flow of liquid. Uncovering a protective film from the outer bread activates the desiccant, and calcium chloride reacts with moisture to form a salt solution that flows through a filter and into the storage bag. After entering the storage bag, the salt solution will not re-evaporate. Absormatic also claims that the rate of absorption can be controlled by changing the properties of the porous material surrounding calcium chloride. The amount of salt and the size of the storage bag also affect the total water absorption capacity of the desiccant. Another feature of this desiccant is that it is shaped like a rod and can be inserted into the wall groove of the container, taking up very little space and minimizing the risk of damage.

Another company, Desiccare's main product, is the Cargo DryPak, available in two sizes. One is a 500 gram pack, suitable for being placed inside the box, and the other is a 1500 gram bag with a lanyard suitable for hanging on a hook inside the container. Desiccare also introduced a temperature indicator card to measure the relative humidity within a packaged environment. Humidity indicator cards can be used with desiccants, especially when transporting sensitive electronic circuits and components. The point on the card that varies with relative humidity (from blue to pink), indicating the level of humidity in an environment. The life of the desiccant can be observed based on the color of the dots on the card. If the dots are already pink, the desiccant needs to be replaced. As long as the used indicator card is placed in the oven for less than a minute, the indicator card can be used again.

Danish Anders Bendt has 20 years of experience in the production of desiccants. The basic raw material used is the “Moller soil” which is only found in the Limfjorden region of Denmark. This soil is made up of the remains of diatoms and plastic soil. The company claims that the structure of diatoms is extremely porous because it consists of thousands of tiny thin-walled capillaries. The surface area per gram of Moller soil is about 50 square meters. Moller soil is used in combination with calcium chloride. The company's desiccant product is heat treated so its particles remain stable even at 100% saturation. These products are called "dry packs" (DRY-BAG) and range in size from 25 grams to 2 kilograms. Anders Bendt claims that its products can absorb 75.86% of its own weight for more than 80 days and can then be disposed of as household waste.

All trademarks shown here are for reference purposes only. They are the property of their respective owners, and we are not authorized to sell items bearing such trademarks.