1. Why are import and export cargoes getting wet?

High-temperature air can contain more water vapor than cold air. For example, at 40 °C, 1m3 air can contain up to 51.20g water vapor, and when the temperature is lowered to 20°C, 1m3 air can only contain up to 17.30g water vapor, and excess 33.9g water vapor. Will condense into water droplets and be removed from the air. That's why we saw the frost in the fall in the summer.

The container is a relatively closed environment. During the shipping process, when the temperature inside the container drops sharply with the external environment, the excess water vapor cannot be quickly removed, and only the water droplets can be condensed into the top and wall of the low temperature container. Dropping onto the goods, this is what we often call the "container rain" phenomenon. At the same time, the wooden floors and goods in the container itself will also be discharged. Goods in this environment will be mildewed, deteriorated, and corroded, causing various losses.

2. Why can container desiccant prevent container cargo from getting wet?

The container desiccant absorbs the water vapor in the container air from the time of installation. The proper amount of desiccant can control the humidity inside the container to a suitable level to ensure that there is no excess condensation in the air when the temperature drops sharply, thus avoiding container fog. The rain is generated to ensure that the goods are transported in a safe and dry environment until unpacking and unloading.

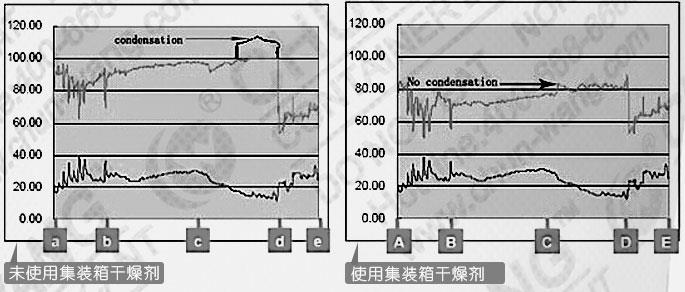

The following figure shows the results of experiments with and without container desiccant:

3. What conditions must the container desiccant meet?

1) Must have high moisture absorption rate and fast moisture absorption rate:

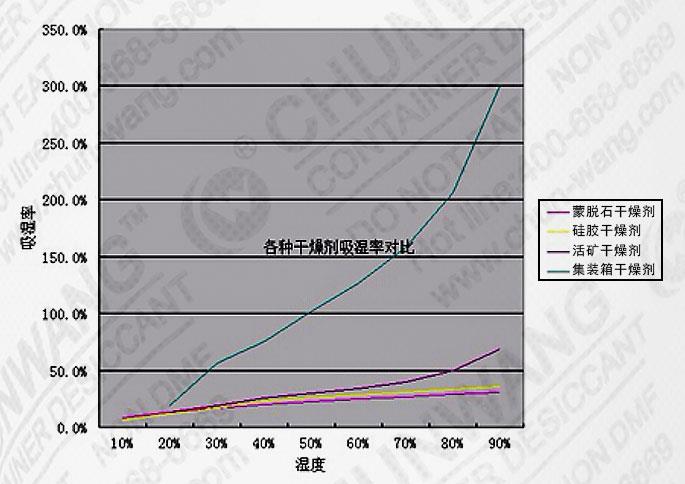

The container space is large, not completely sealed, and the temperature difference between day and night during the maritime transportation process often reaches 50-60 ° C. Therefore, the container desiccant must have a rapid and large moisture absorption capacity, and rapidly reduce the humidity of the air inside the container, thereby ensuring a sharp drop in temperature. No condensation is produced. The container desiccant has a maximum moisture absorption capacity of 200%-300% at a temperature of 25 ° C and a relative humidity of 95%. It is more than 8 times that of the traditional montmorillonite desiccant and silica gel desiccant. It is a live ore desiccant. More than 5 times. As shown below:

2) Must have the ability to continuously absorb moisture for a long time:

The container is not completely confined, and it communicates with the outside air continuously during the maritime transportation process. The external water vapor can continuously enter the container. At the same time, the container shipping time can be up to 60 days, so the container desiccant must be able to continuously absorb moisture for 60 days or longer, which is required to effectively reduce the humidity of the air inside the container.

3) Must have a large span of operating temperature:

In extreme cases, the temperature may be as high as 70-80 ° C and as low as -10 to -20 ° C. It is required that the desiccant can maintain the moisture absorption capacity at these temperatures and reduce the humidity of the air inside the container.

4) Safe and reliable, no leakage risk:

Most of the container desiccant is calcium chloride, which becomes liquid after moisture absorption. In the process of transportation, the package is leaked or the desiccant drops, which may cause the solution in the desiccant to seep out into the container, which will increase the humidity of the container and increase the humidity. The risk of cargo being wet.

5) Must comply with environmental protection requirements:

At present, Europe, the United States and the world are paying more and more attention to the environmental protection requirements of imported goods. The desiccant as a packaging auxiliary must meet all environmental protection requirements in order to meet the needs of export goods. Such as: meet ROHS and REACH requirements, do not contain DMF, can be treated as general waste.

All trademarks shown here are for reference purposes only. They are the property of their respective owners, and we are not authorized to sell items bearing such trademarks.